[ez-toc]

How is a vinyl record made

How is a vinyl record made? Here are our 16 steps to making a vinyl record

1. Mastering for vinyl

From client supplied audio master we will re-master specifically for vinyl records, setting all the appropriate levels and parameters for the optimum sound reproduction on a vinyl record.

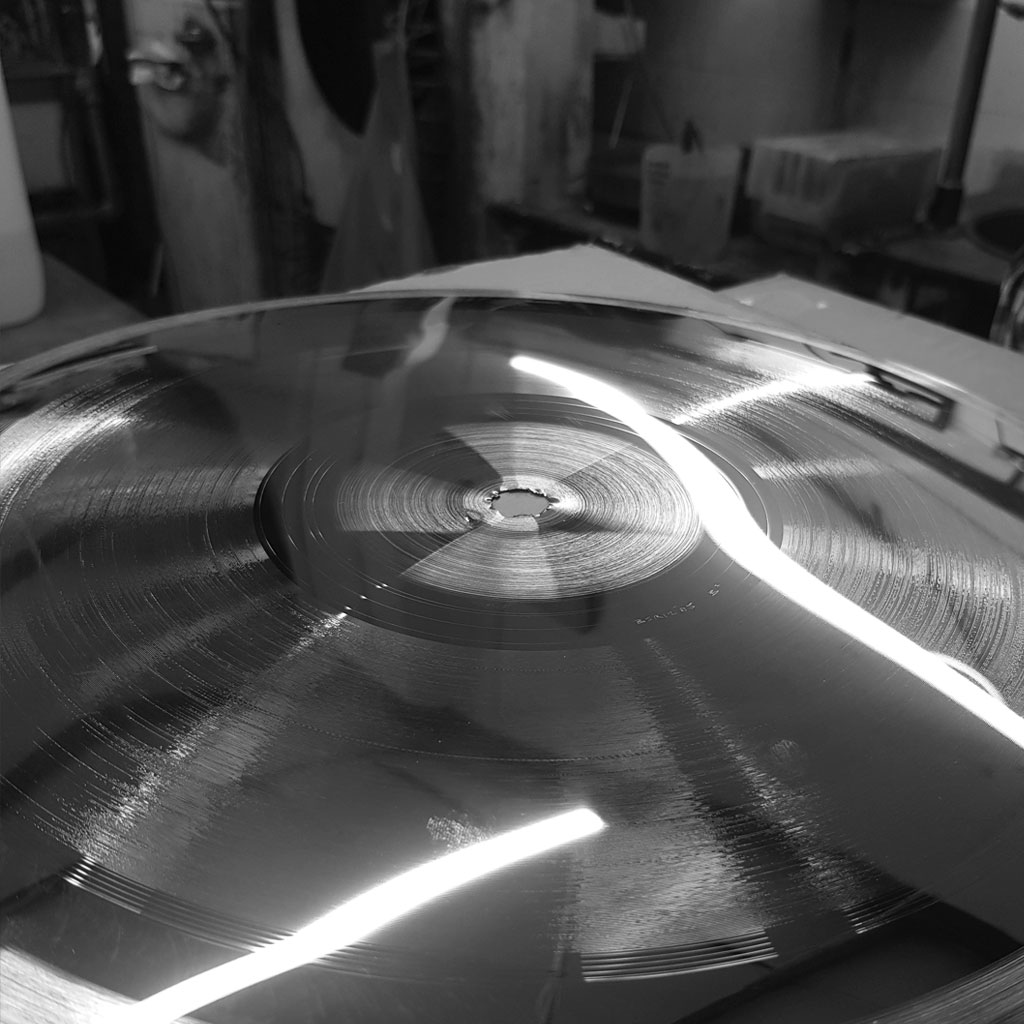

2. Cutting

We will cut using a very special lathe with a ruby tipped cutter to etch a continuous sound groove into a lacquered disc. This is inspected under a electro-microscope to ensure the macro details are all present and correct.

3. Galvanics

From a lacquered disc it is then sprayed with tin chloride and liquid silver and passes through a chemical bath to fuse and stabilise these elements.

4. Stamper Finishing

This will then be finished to safe and manageable plate.

5. Positive and negative plates

Then positive & negative plates are created.

6. Stamper

From these plates a final stamper plate is created which is used for the pressing of the vinyl records.

7. Labels Baking

Most people don’t realise but the centre labels are actually applied within the press and must be baked in an oven for 24-hours to remove all moisture to ensure a perfect fit.

8. Vinyl Pellets

Polyvinyl chloride pellets are selected.

9. 100+ Colours

If a colour is requested of which we have more than 100 to choose from then the appropriate colour is selected and added to the “mix”

10. Vinyl Puck

The Polyvinyl chloride “mix” is fed into a hopper which is then heated to create a 130-degree hot rubbery dough/ puck, the paper centre labels are positioned Top – Side A and Bottom – Side B while still hot and pliable are then pressed under enormous pressure (100 tonnes) to create the actual vinyl record.

11. Pressing

Pressed Records are then matched with their appropriate printed packing (sleeves, inserts etc..) and packed accordingly.

12. Our Test Pressings

As vinyl record manufacturing has a lot more room for error over say CD or Digital releases so above and beyond all the in-house checks we do it’s (in our opinion) essential that the end result will meet the clients expectations which is why we produce 10 Test Pressings for a final check prior to the main pressing.

13. Test Pressings Insertion

Test Pressing are thoroughly inspected and put into paper sleeves

14. Packing Quality Control

There are several Quality Control checks throughout the whole process the final being a full visual and sound check just before packing

15. Shrinkwrap

Records can if required be shrink wrapped or bagged and additional printed labels applied.

16. Boxed for collection

Records are boxed into a pizza style box and then 4 of these pizza boxes are then put into an outer box to ready for despatch